Difference between revisions of "Gasket"

m |

m |

||

| Line 18: | Line 18: | ||

| − | { | + | |

| − | + | {{Automobile configurations}} | |

Revision as of 16:22, 17 December 2007

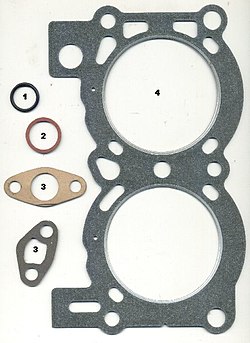

A gasket is a mechanical seal that serves to fill the space between two objects, generally to prevent leakage between the two objects while under compression. Gaskets are commonly produced by cutting from sheet materials, such as gasket paper, rubber, silicone, metal, felt, fiberglass, or a plastic polymer. Gaskets for specific applications may contain asbestos. It is usually desirable that the gasket be made from a compressible or slightly compressible material such that it tightly fills the space it is designed for, including any slight irregularities.

One of the more desirable properties of an effective gasket in industrial applications for compressed fiber gasket material is the ability to withstand high compressive loads. Most industrial gasket applications involve bolts exerting compression well into the 14 MPa (2000 psi) range or higher. Generally speaking, there are several truisms that allow for best gasket performance. One of the more tried and tested is: "The more compressive load exerted on the gasket, the longer it will last". There are several ways to measure a gasket material's ability to withstand compressive loading. The "hot compression test" is probably the most accepted of these. Most manufacturers of gasket materials will provide or publish these results.

See also

Sources:

- Bickford, John H.: An Introduction to the Design and Behavior of Bolted Joints, 3rd ed., Marcel Dekker, 1995, pg. 5

- Latte, Dr. Jorge and Rossi, Claudio: High Temperature Behavior of Compressed Fiber Gasket Materials, and an Alternative Approach to the Prediction of Gasket Life, FSA presented Paper, 1995, pg. 16