Pushrod

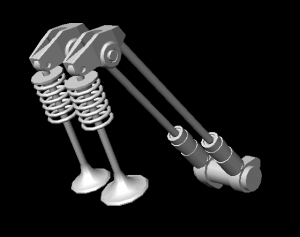

An overhead valve (OHV) engine, also called pushrod engine or I-head engine is a type of piston engine that places the camshaft in the cylinder block (usually beside and slightly above the crankshaft in a straight engine or directly above the crankshaft in the V of a V engine) and uses pushrods or rods to actuate rocker arms above the cylinder head to actuate the valves. Lifters or tappets reside in the engine block between the camshaft and pushrods. The later overhead cam (OHC) design avoids the use of pushrods by putting the camshaft in the cylinder head.

In 1949, Oldsmobile introduced the Rocket V8. It was the first high-compression I-head design, and is the archetype for most modern pushrod engines. General Motors is the world's largest pushrod engine producer with engines such as the 3800 Series III Supercharged V6 260 hp, 280 lbft, LS7 Chevrolet Corvette 7.0 L V8 Engine 505 hp, 475 lbft and LS4 5.3 L DOD V8 303 hp, 323 lbft.

Few pushrod type engines remain in production outside of the United States market. This is in part a result of some countries passing laws to tax engines based on displacement due to the fact that displacement is somewhat related to the emissions and fuel efficiency of an automobile. This has given OHC engines a regulatory advantage in those countries, which resulted in few manufacturers wanting to design both OHV and OHC engines.

However, in 2002, Chrysler introduced a new pushrod engine: a 5.7 L Hemi engine. The new Chrysler Hemi engine presents advanced features such as variable displacement technology and has been a popular option with buyers. The Hemi was on the Ward's 10 Best Engines list for 2003 through 2007. Chrysler also produced the world's first production variable valve OHV engine with independent intake and exhaust phasing. The system is called CamInCam, and was first used in the 600hp SRT-10 engine for the 2008 Dodge Viper.

History

In automotive engineering, an overhead valve internal combustion engine is one in which the intake and exhaust valves and ports are contained in the cylinder head.

The original overhead valve or OHV piston engine was developed by the Scottish-American David Dunbar Buick. It employs pushrod-actuated valves parallel to the pistons and this is still in use today. This contrasts with previous designs which made use of side valves and sleeve valves.

Nowadays, side-valves have virtually disappeared (except perhaps in lawn-mower engines) and valves are almost all "overhead". However most are now driven more directly by the overhead camshaft system and these are designated OHC instead (either SOHC or DOHC).

Advantages

Pushrod engines have specific advantages:

- Smaller overall packaging — Because of the camshaft's location inside the engine block, pushrods are more compact than an overhead cam engine of comparable displacement. For example, Ford's 4.6 L OHC modular V8 is larger than the 5.0 L I-head Windsor V8 it replaced. GM's 4.6 L OHC Northstar V8 is slightly taller and wider than GM's larger displacement 5.7 to 7.0 L I-head LS V8. The Ford Ka uses the venerable Kent Crossflow pushrod engine to fit under its low bonnet line.

- Less complex drive system — Pushrod engines have a less complex drive system to time the camshaft when compared with OHC engines. Most OHC engines drive the camshaft or camshafts using a timing belt, a chain or multiple chains. These systems require the use of tensioners which add some complexity to the engine. In contrast a pushrod engine has the camshaft positioned just above crankshaft and can be run with a much smaller chain or even direct gear connection.

Limitations

Some specific problems that remain with pushrod engines:

- Limited engine speeds or RPM — Pushrod engines have more valvetrain moving parts thus more valvetrain inertia and mass, as a result they suffer more easily from valve "float" and may exhibit a tendency for the pushrods, if improperly designed, to flex or snap at high engine speeds. Therefore, pushrod engine designs cannot revolve ("rev") at engine speeds as high as OHC designs.

Modern pushrod engines are usually limited to about 6,000 RPM to 8,000 RPM in production cars and 9,000 RPM to 10,500 RPM in racing applications. In contrast, many modern DOHC engines may have rev limits from 6,000 RPM to 9,000 RPM in road legal car engines and up to 18,000 RPM in current Formula One race engines using pneumatic valve springs. High-revving pushrod engines are normally solid (mechanical) lifter designs, flat and roller. In 1969, Chevrolet offered a Corvette and a Camaro model with a solid lifter cam pushrod V8 (the ZL-1) that could rev to 8,000 RPM. The Volvo B18 and B20 engines can rev to more than 7,000 RPM with their solid lifter camshaft. However, the LS7 of the C6 Corvette Z06 is the first production hydraulic roller cam pushrod engine to have a redline of 7100 RPM.

- Limited cylinder head design flexibility — OHC engines benefit substantially from the use of multiple valves as well as much greater freedom of component placement and intake and exhaust port geometry. Most modern pushrod engines have two valves per cylinder, while many OHC engines can have three, four or even five valves per cylinder to achieve greater power. Though multi-valve pushrod engines exist their use is somewhat limited due to their complexity and is mostly restricted to low and medium speed diesel engines. In pushrod engines the size and shape of the intake ports as well as the position of the valves are limited by the pushrods.

1994 Mercedes/Ilmor Indianapolis 500 engine

The Indy 500 race in Indianapolis each year bears some vestige of its original purpose as a proving ground for automobile manufacturers, in that it once gave an advantage in engine displacement to engines based on stock production engines, as distinct from out-and-out racing engines designed from scratch. One factor in identifying production engines from racing engines was the use of pushrods, rather than the overhead cams used on most modern racing engines; Mercedes-Benz realized before the 1994 race that they could very carefully tailor a purpose-built racing engine using pushrods to meet the requirements of the Indy rules and take advantage of the 'production based' loophole but still design it to be a state of the art racing engine in all other ways, without any of the drawbacks of a real production-based engine. They entered this engine in 1994, and, as expected, dominated the race. After the race, the rules were changed in order to reduce the amount of boost pressure allowed to be supplied by the turbocharger. The inability of the engine to produce competitive power output after this change caused it to become obsolete after just the one race. Mercedes-Benz knew this beforehand, deciding that the cost of engine development was worth one win at Indianapolis.

See also

External links

- Pushrod (OHV), SOHC and DOHC engine animated diagrams

- LS7 torque and power by rpm chart

- Ferrari Enzo: The Engine

- The Pushrod Engine Finally Gets its Due